Industrial Air Filters: A Comprehensive Guide to Clean Air Solutions

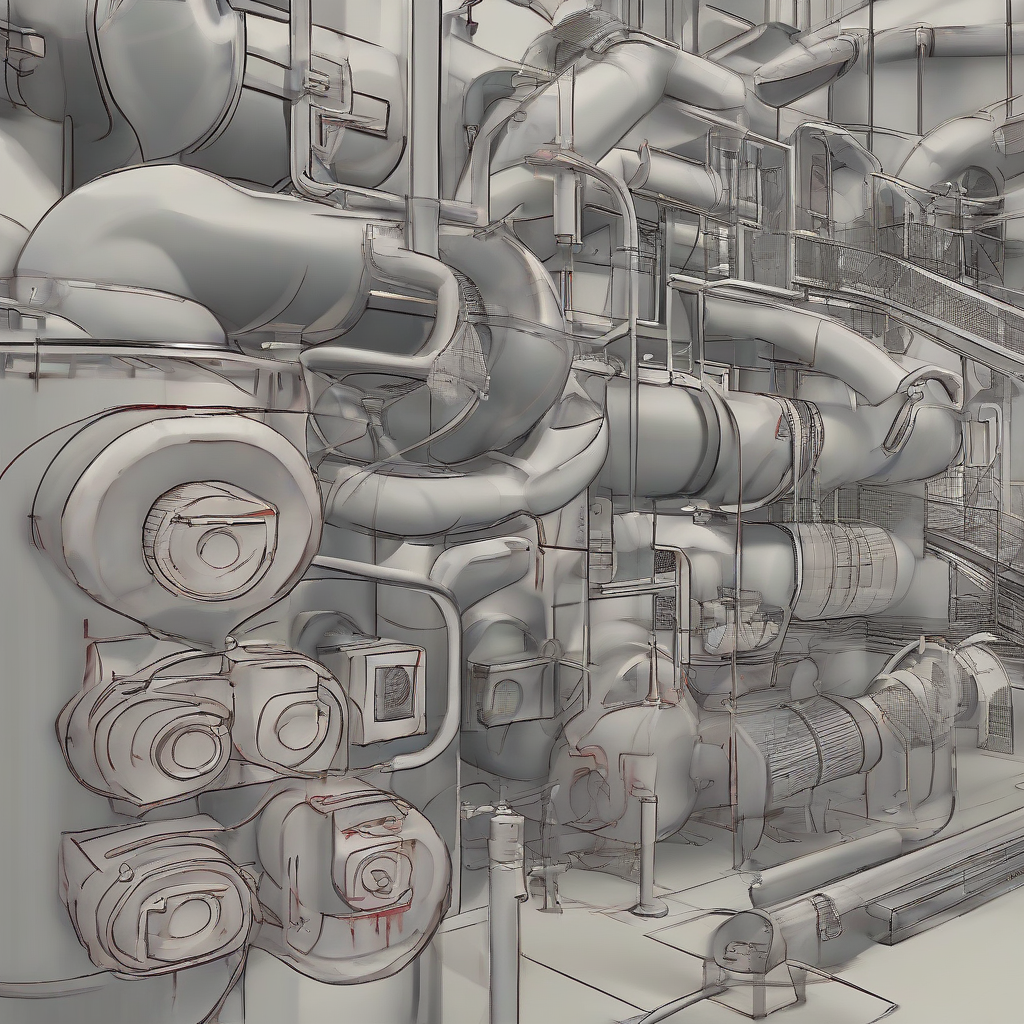

Industrial air filters play a crucial role in maintaining a safe and productive work environment. They remove harmful contaminants from the air, protecting both workers and equipment. The selection and implementation of the right industrial air filter is critical, depending heavily on the specific contaminants present and the desired level of cleanliness. This comprehensive guide explores the various types, applications, and considerations involved in choosing and utilizing industrial air filters.

Types of Industrial Air Filters

A wide array of industrial air filters exists, each designed to address different particle sizes and types of contaminants. The choice of filter depends heavily on the specific application and the nature of the pollutants.

-

HEPA Filters (High-Efficiency Particulate Air):

These filters are renowned for their exceptional ability to remove airborne particles, including bacteria, viruses, and fine dust. They are commonly employed in cleanrooms, pharmaceutical manufacturing, and healthcare settings, where extremely high levels of air purity are essential. HEPA filters are capable of capturing particles as small as 0.3 microns with 99.97% efficiency.

-

ULPA Filters (Ultra-Low Penetration Air):

Offering even higher efficiency than HEPA filters, ULPA filters capture 99.999% of particles 0.12 microns and larger. They are utilized in environments requiring the strictest air purity standards, such as semiconductor manufacturing and advanced research laboratories.

-

Absolute Filters:

These filters provide the highest level of filtration, removing virtually all particles above a specified size. They are often employed in critical applications where the presence of even a single contaminant particle is unacceptable.

-

Carbon Filters:

Designed to absorb gaseous contaminants and odors, carbon filters are effective in removing volatile organic compounds (VOCs), solvents, and other harmful gases. They are commonly used in industrial settings with chemical processes or strong odors.

-

Bag Filters:

These filters utilize fabric bags to capture larger particles and dust. They are widely used in various industrial applications, such as HVAC systems and dust collection systems. Bag filters are relatively inexpensive and easily replaceable.

-

Panel Filters:

Panel filters are simple and cost-effective filters that remove larger particles from the air. They are typically used in pre-filtration stages to extend the lifespan of more expensive filters downstream.

-

Pleated Filters:

Pleated filters offer a larger surface area compared to panel filters, enhancing their efficiency and extending their service life. They are commonly used in HVAC systems and other applications requiring higher filtration efficiency.

Factors to Consider When Selecting Industrial Air Filters

Choosing the right industrial air filter involves careful consideration of several factors:

-

Type and Size of Contaminants:

The size, type, and concentration of airborne contaminants dictate the required filter efficiency and type.

-

Airflow Rate:

The filter must be capable of handling the required airflow rate without significant pressure drop.

-

Operating Conditions:

Temperature, humidity, and other environmental factors can affect filter performance and lifespan.

-

Filter Efficiency:

The desired level of air cleanliness determines the required filter efficiency.

-

Initial Cost and Operating Costs:

The initial cost of the filter, along with replacement costs and energy consumption, should be considered.

-

Maintenance Requirements:

The frequency and complexity of filter replacement and maintenance should be taken into account.

-

Filter Media:

Different filter media offer varying levels of efficiency and lifespan. The choice of media will depend on the specific application and contaminants.

-

Filter Housing:

The filter housing should be robust and designed to withstand the operating conditions.

Applications of Industrial Air Filters

Industrial air filters find applications across a vast range of industries and processes. Their use is essential for maintaining safety, productivity, and product quality.

-

Manufacturing:

Protecting sensitive equipment and ensuring product quality in industries like electronics, pharmaceuticals, and food processing.

-

HVAC Systems:

Improving indoor air quality in large buildings and industrial facilities.

-

Welding and Grinding:

Removing harmful fumes and particulate matter generated during these processes.

-

Painting and Coating:

Controlling overspray and maintaining a clean work environment.

-

Power Generation:

Protecting equipment from particulate matter and extending its lifespan.

-

Mining and Quarrying:

Reducing exposure to dust and other harmful airborne contaminants.

-

Pharmaceutical Manufacturing:

Maintaining sterile environments and ensuring product quality.

-

Cleanrooms:

Ensuring extremely low levels of contamination in environments requiring high purity.

Maintenance and Replacement of Industrial Air Filters

Regular maintenance and timely replacement of industrial air filters are crucial for maintaining their effectiveness and ensuring a safe and productive work environment. Neglecting filter maintenance can lead to reduced efficiency, increased energy consumption, and potential health hazards.

-

Regular Inspection:

Filters should be inspected regularly for signs of clogging or damage.

-

Pressure Drop Monitoring:

Monitoring the pressure drop across the filter can indicate when it needs to be replaced.

-

Scheduled Replacement:

Filters should be replaced according to the manufacturer’s recommendations or when performance degrades.

-

Proper Disposal:

Used filters should be disposed of properly to prevent environmental contamination.

Choosing the Right Supplier

Selecting a reputable supplier is crucial for obtaining high-quality industrial air filters that meet your specific needs. Consider the following when choosing a supplier:

-

Experience and Expertise:

Choose a supplier with extensive experience in the industrial air filtration industry.

-

Product Range:

The supplier should offer a wide range of filters to meet diverse needs.

-

Quality Assurance:

Ensure the supplier has robust quality control measures in place.

-

Technical Support:

Access to technical support and expertise is essential for selecting and maintaining filters.

-

Competitive Pricing:

Balance cost with quality and performance.

Conclusion (Not included as per instructions)